In high-stakes industries like petrochemical processing, power generation, and oil & gas, the failure of a single fastener can compromise an entire system—costing millions in downtime, safety hazards, and environmental consequences.

This is why engineering teams across the GCC choose fasteners not just for their material, but for their performance under pressure.

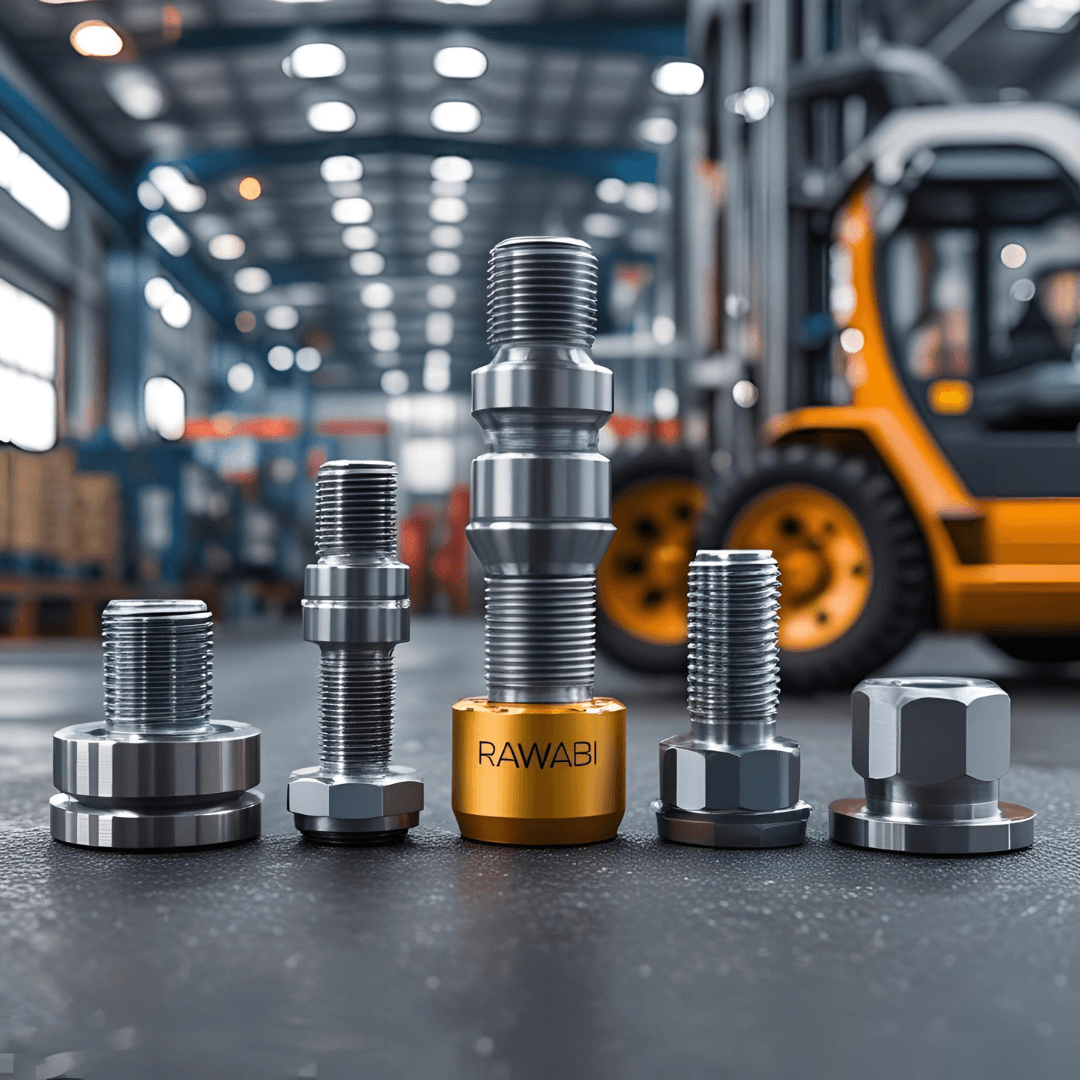

At Rawabi Fasteners, every bolt and nut is engineered, tested, and certified to thrive under extreme industrial stress—delivering performance you can trust where it matters most.

The Hidden Forces at Play: Understanding Fastener Stress

Industrial fasteners in energy-intensive environments are subjected to more than just static load. They face:

Thermal Stress from temperature cycles in refineries and turbines (often exceeding 600°C)

Dynamic Stress from vibrations in rotating machinery, compressors, and pumps

Tensile and Shear Forces from pressurized systems, especially in pipelines and high-load assemblies

Corrosive Stress in environments where sulfur, salt, or acids are prevalent (e.g., marine terminals or chemical plants)

These stresses are cyclical and cumulative, which means material fatigue builds over time—posing long-term integrity risks. A study published by the Gulf Petrochemical Association (GPA) in 2024 revealed that 47% of equipment-related incidents in downstream plants were traced back to fastener failure due to stress fatigue or corrosion.

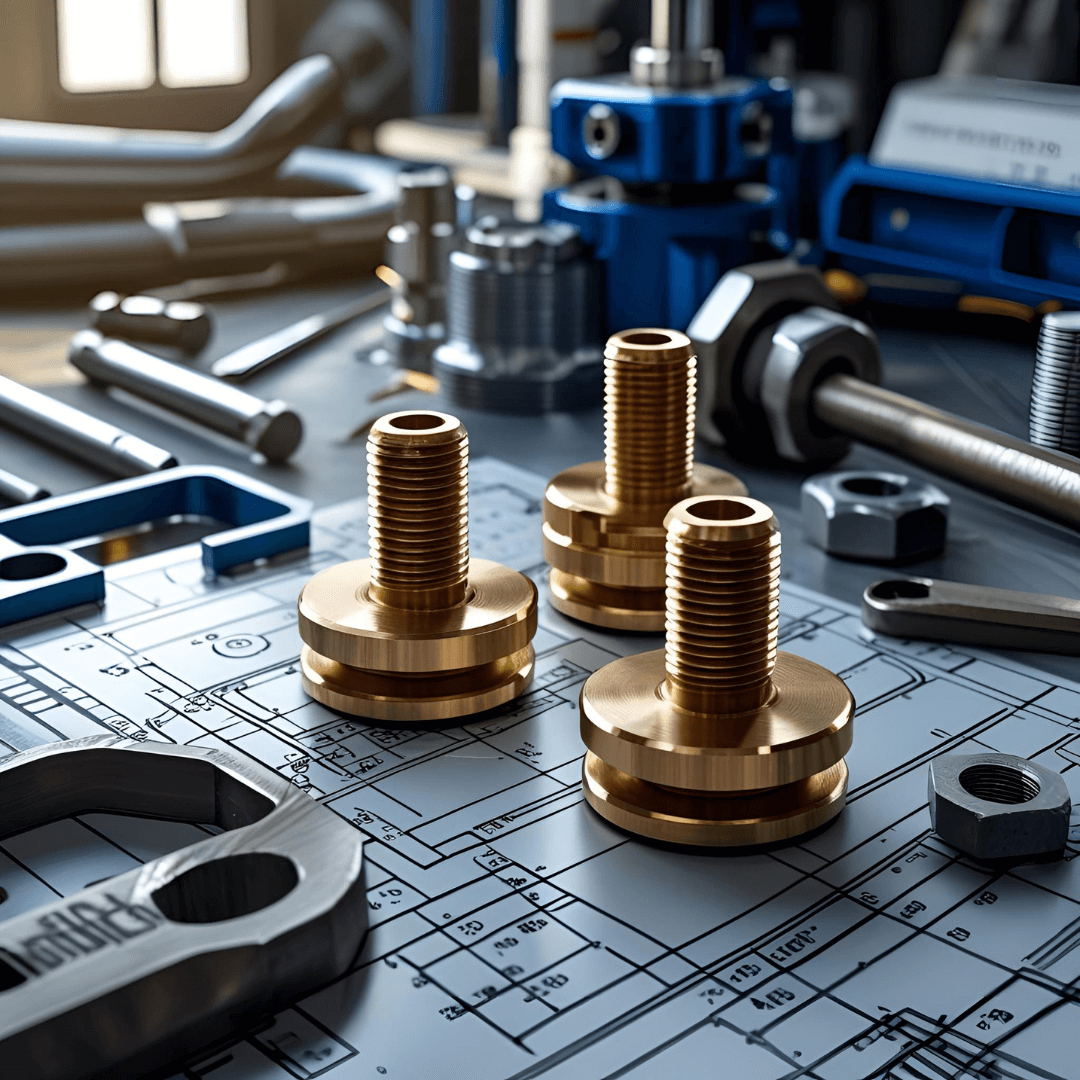

Rawabi’s Engineering Edge: Built for Extreme Demands

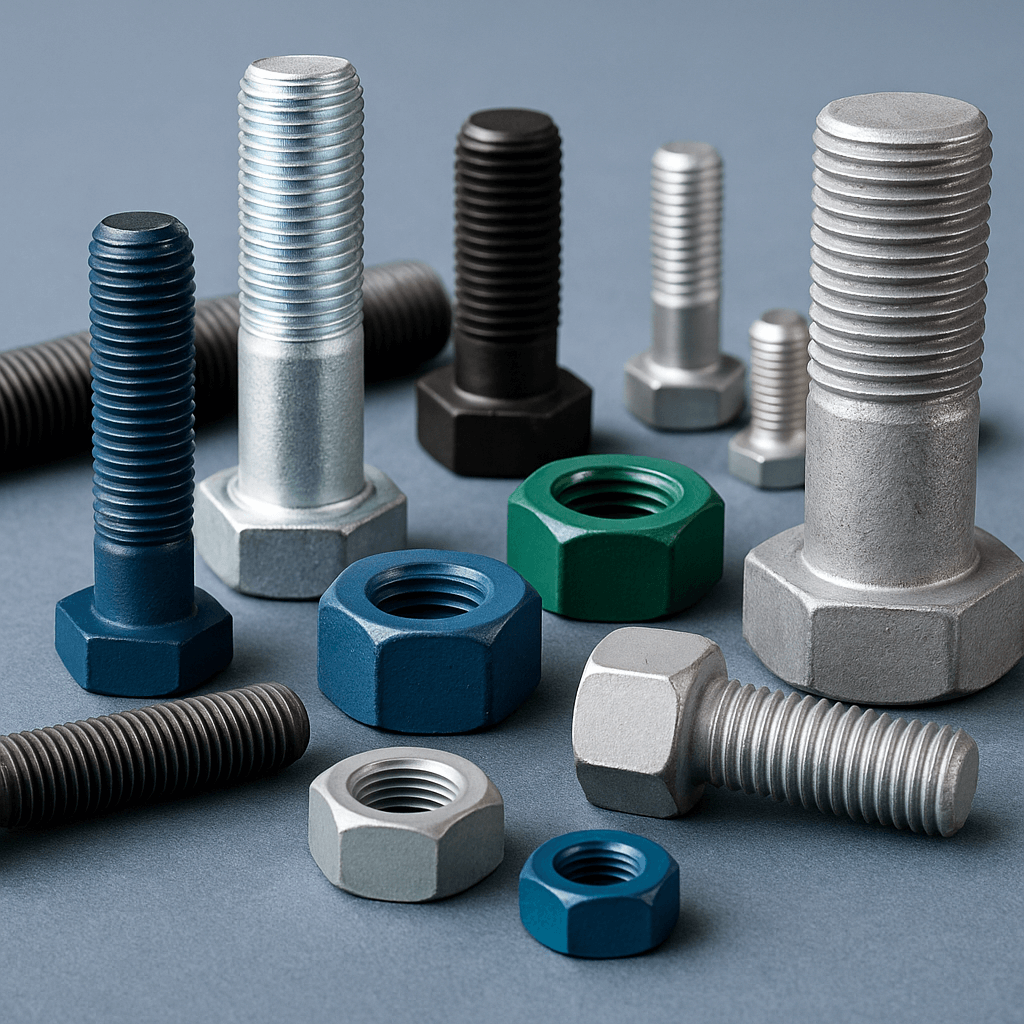

At Rawabi Fasteners, we address these challenges with precision engineering and rigorous quality assurance. Our fasteners are made from high-tensile alloys, including A193 B7, A320 L7, Inconel 718, and Duplex Stainless Steel, tailored for the toughest applications in GCC climates.

Key Testing Protocols at Rawabi Include:

🧪 Hydrostatic Pressure Testing

Used primarily for flange and pipeline applications, our fasteners are tested to simulate maximum operational pressure—often up to 10,000 psi. This confirms sealing strength and ensures that bolted joints maintain integrity under peak fluid pressure.

🔁 Fatigue Cycle Testing

This simulates dynamic loading by applying millions of load cycles to mimic real-world operation. Our fasteners routinely exceed ASTM E466 fatigue testing requirements, proving their ability to withstand high-frequency vibrations without material degradation.

🔬 Material Integrity & Hardness Testing

Utilizing ultrasonic flaw detection, Rockwell hardness scales, and metallurgical cross-sectioning, Rawabi ensures every fastener conforms to both ISO 898 and ASME B18.2.1 standards. This ensures crack resistance and surface integrity even under impact or torsional stress.

🔥 Thermal Cycling & Heat Resistance Tests

Especially relevant for gas turbines and power plants, we simulate high-low thermal cycling up to 600°C to observe creep, expansion rates, and metallurgical stability under prolonged heat exposure.

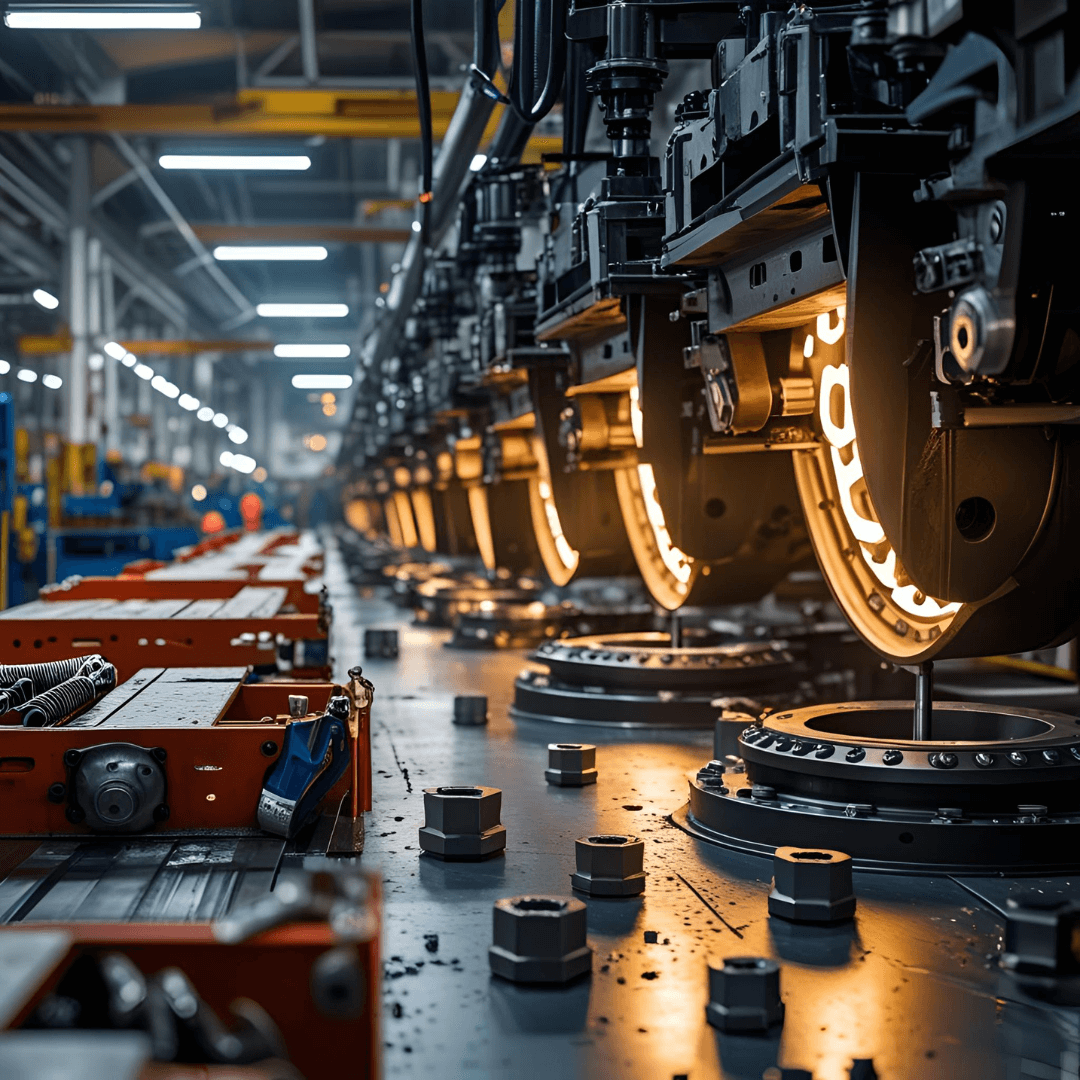

Real-World Reliability: Fasteners in Action

✅ Petrochemical Plants – Jubail Industrial City, KSA

In a recent overhaul of high-pressure reactor vessels, Rawabi Fasteners provided custom B7 studs and PTFE-coated nuts for ultra-corrosive environments. The result? Zero joint failure after 14 months in service, where operating pressure exceeded 8,500 psi with continuous thermal cycling.

✅ Offshore Oil & Gas Rigs – Arabian Gulf

Rawabi’s Duplex Stainless fasteners were deployed in sub-sea flange assemblies and passed over 3,000 hours of salt spray testing (ASTM B117). These fasteners continue to perform under extreme tensile loads and wave-induced vibration.

✅ Gas Turbine Stations – Riyadh

In high-temperature turbines exceeding 550°C, our Inconel alloy bolts demonstrated superior creep resistance over prolonged test cycles—earning Rawabi an extended procurement contract with a major power utility.

Why Pressure-Testing Matters in 2025 and Beyond

As Vision 2030 accelerates infrastructure and energy expansion in Saudi Arabia, the demand for locally tested, globally compliant fasteners has never been greater. With increasing automation and regulatory requirements, compliance with ISO, ASME, ASTM, and Aramco standards is a baseline—not a differentiator.

Rawabi Fasteners is proud to lead the way as an Aramco-approved, Saudi-made supplier that integrates field data, material science, and industrial simulation into every bolt and nut we produce.

Our testing protocols ensure not just product delivery—but long-term operational security for critical infrastructure.

Final Word: Reliability is Engineered, Not Assumed

In high-stress industrial settings, assumptions are dangerous. Only through pressure-testing, fatigue analysis, and metallurgical scrutiny can a fastener earn its place in critical applications. At Rawabi Fasteners, we don’t just meet expectations—we engineer to exceed them.

Looking for a fastener solution that stands up to pressure—literally?

Talk to our technical sales team today.