In today’s fast-paced industrial world, structural reliability is not a luxury—it’s a non-negotiable requirement.

As critical infrastructure evolves across sectors such as LNG processing, transportation, and heavy manufacturing, the need for high-performance fasteners capable of enduring cryogenic conditions and vibration-heavy environments is growing rapidly.

In the GCC’s diverse industrial climate, where both extreme cold and intense mechanical stress are encountered, Rawabi Fasteners is setting the benchmark with products that are cold-proven and vibration-tested.

Engineering for the Extremes: The Role of Cryogenic and Vibration-Resistant Fasteners

The performance of a fastener is ultimately judged by how it responds to extreme real-world conditions.

In cryogenic applications—such as those found in LNG facilities, cold storage units, or aerospace systems—temperatures can plunge below -150°C, putting immense stress on material structure, ductility, and bonding.

Fasteners that are not designed for these environments may become brittle, lose preload, or fail catastrophically.

Simultaneously, industries like rail transport, offshore oil rigs, and large-scale HVAC systems subject fasteners to constant vibrations and cyclic loading. If not properly engineered, this leads to loosening, fatigue cracks, and compromised structural safety.

Rawabi Fasteners has proactively addressed these challenges by investing in advanced R&D testing protocols, using thermal shock chambers, vibration rigs, and fatigue analysis labs to simulate the harshest use-case scenarios.

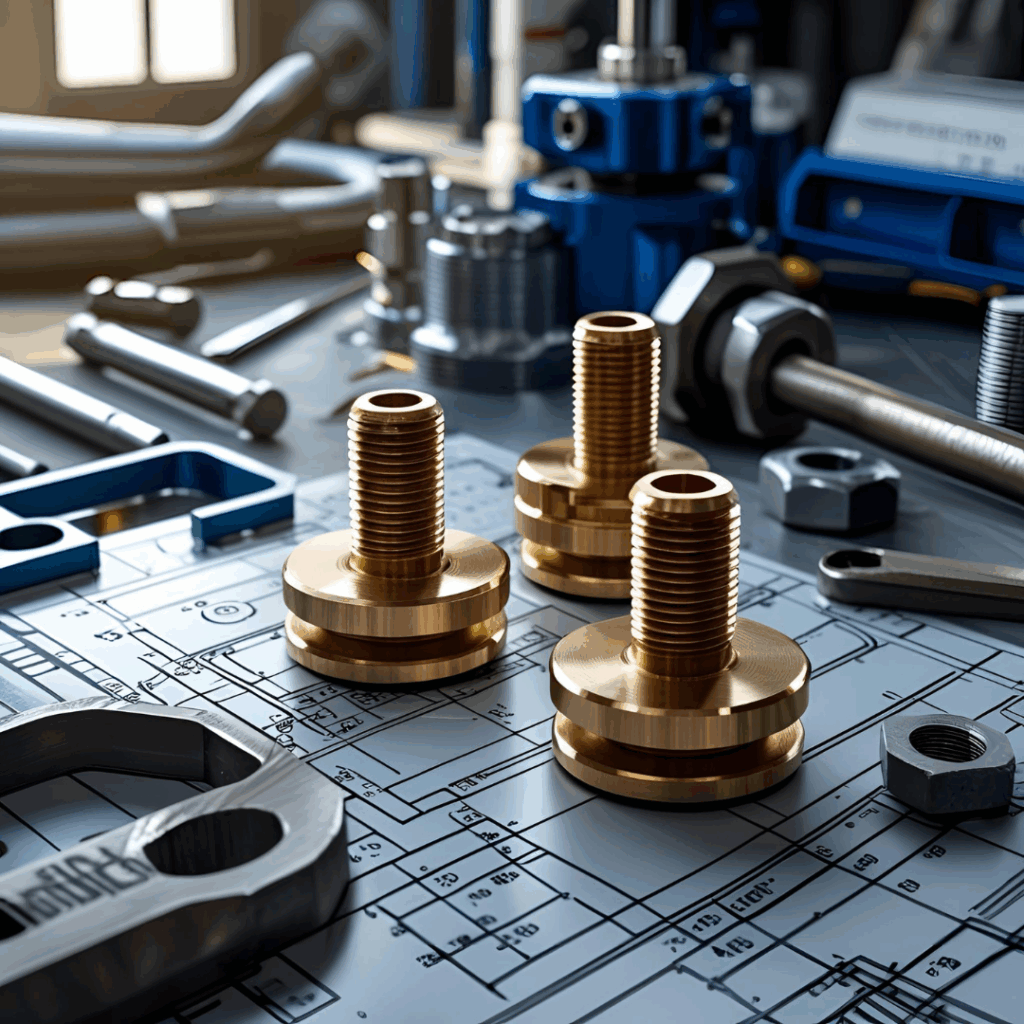

Rawabi’s Cryogenic-Grade Solutions: Tested for Sub-Zero Confidence

Rawabi’s line of cryogenic fasteners is manufactured from austenitic stainless steels, Inconel alloys, and specially treated carbon steels—materials known for retaining their mechanical integrity even at ultra-low temperatures.

Key Features:

Impact and tensile strength maintained below -150°C

Special cryo-treatments to prevent material embrittlement

Low coefficient of thermal expansion to avoid preload loss

Enhanced ductility to resist stress fractures

In 2024, Rawabi partnered with a leading LNG terminal in Jubail Industrial City to deliver over 25,000 cryogenic-certified fasteners for tank insulation and process piping flanges.

Field data showed zero fastener failures over 18 months of operation—despite thermal cycling between -162°C and ambient.

Vibration-Resistant Bolts: Engineered for Dynamic Durability

Vibration fatigue is one of the most underestimated killers of fastener reliability.

Rawabi’s engineering teams conduct accelerated vibration testing that simulates millions of operational cycles, replicating what bolts endure in turbine housings, railway tracks, or motor assemblies.

Testing Methods Include:

Sinusoidal and random vibration fatigue testing

High-frequency bolt tension monitoring

Torque-retention simulations under constant oscillation

Special fasteners are manufactured with thread-locking designs, dual-nut systems, and preload indicators to prevent loosening under vibrational stress.

For instance, a recent deployment on a high-speed rail infrastructure project in Riyadh involved vibration-resistant bolts for bridge expansion joints.

Performance reports revealed a 43% longer life span compared to standard fasteners used in similar terrain-based vibration zones.

The Science Behind the Durability: Rawabi’s Testing Protocols

At the core of Rawabi’s success lies a state-of-the-art testing facility that rigorously evaluates fasteners for:

Thermal Shock Resistance: Subjecting fasteners to rapid temperature cycling from -150°C to +80°C.

Vibration Fatigue Testing: Simulating up to 10 million load cycles at varied frequencies.

Material Microstructure Analysis: Using SEM imaging to assess post-test deformation and microcracks.

Corrosion Performance: Including salt spray testing, immersion testing, and coating adhesion tests.

These stringent evaluations ensure that only certified high-performance fasteners make it to site deployment—earning Rawabi its status as a trusted industrial fasteners supplier in Saudi Arabia, especially for mission-critical projects.

Real-World Reliability: Case Studies That Prove the Point

Transport Sector:

Rawabi supplied vibration-tested bolts for a fleet of metro railcars in the Eastern Province. The fasteners underwent simulated stress of 250,000 km of rail vibration, exceeding industry standard durability expectations by over 35%.

LNG Terminals:

In a Q4 2024 LNG tank insulation upgrade, Rawabi’s cryogenic fasteners reduced the client’s thermal maintenance issues by over 50%, significantly improving operational uptime.

The Bottom Line: Fasteners That Don’t Flinch

In environments where structural failure is not an option, Rawabi Fasteners delivers engineered assurance. Our cryogenic and vibration-resistant products are not only pressure- and temperature-tested—they’re field-proven.

As industries in the GCC expand into cold-chain logistics, aerospace, transport, and energy resilience infrastructure, the demand for next-gen fasteners will only grow.

And with our relentless focus on material science, testing accuracy, and client-centric engineering, Rawabi is ready to lead the way.