In the harsh operating environments of the Gulf Cooperation Council (GCC) region, fasteners face relentless threats—from saline coastal atmospheres to high-temperature petrochemical facilities.

For infrastructure to remain intact and safe, the integrity of every nut and bolt matters. That’s where advanced fastener coatings come into play, offering engineered protection that dramatically extends fastener life and reduces maintenance costs. At Rawabi Fasteners, we specialize in corrosion-resistant fasteners GCC, offering some of the most advanced coating technologies available in Saudi Arabia’s industrial sector.

The Role of Coatings in Fastener Performance

Fastener coatings are not just cosmetic—they are engineered layers that shield against environmental degradation, chemical attack, and mechanical wear. A well-applied coating can prevent rust, reduce galling, enhance torque control, and significantly extend service intervals.

In a region like the GCC, where industrial fasteners Saudi Arabia must endure extreme humidity, high salinity (especially in marine and offshore applications), and exposure to corrosive chemicals in oil & gas settings, choosing the right coating is critical to project success and cost-efficiency.

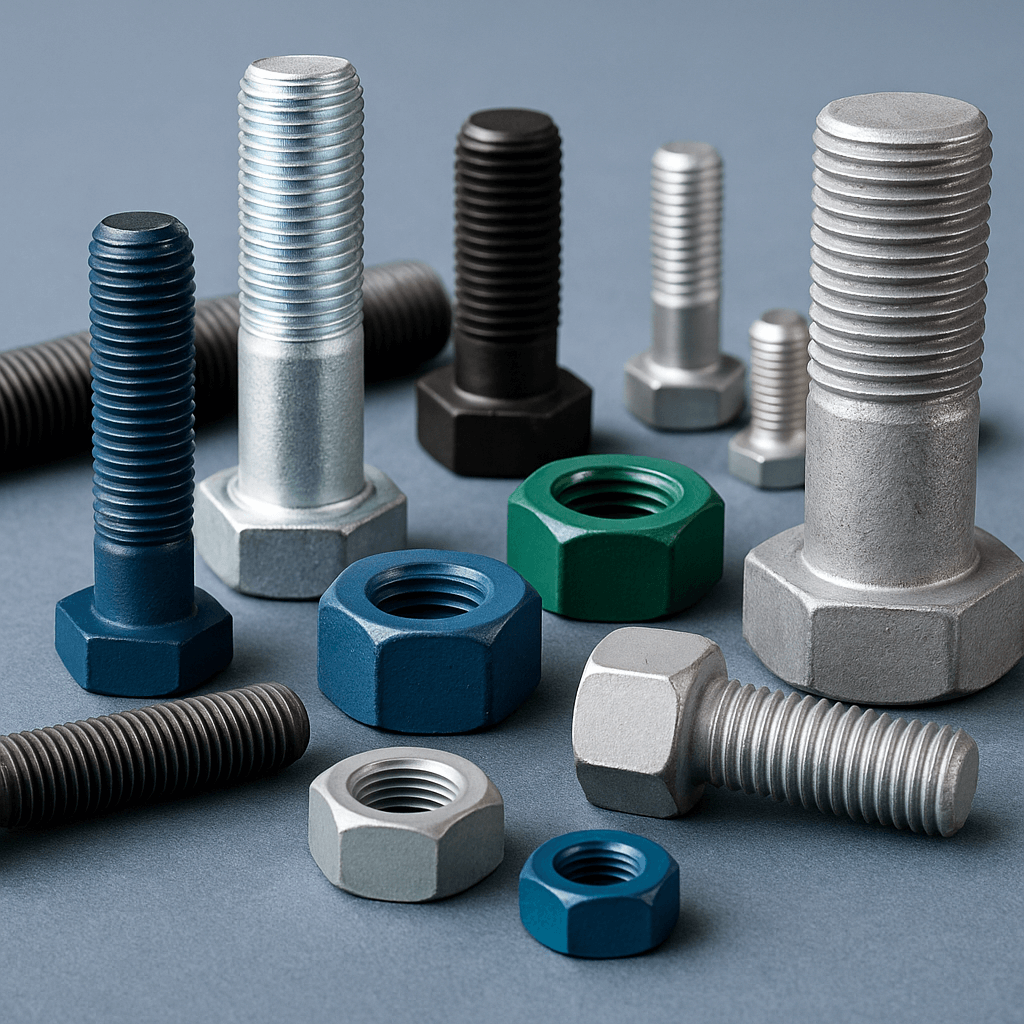

Types of Fastener Coatings Offered by Rawabi Fasteners

As a leading Aramco-certified fasteners supplier KSA, Rawabi Fasteners offers a robust selection of high-performance coating solutions tailored to specific industry demands:

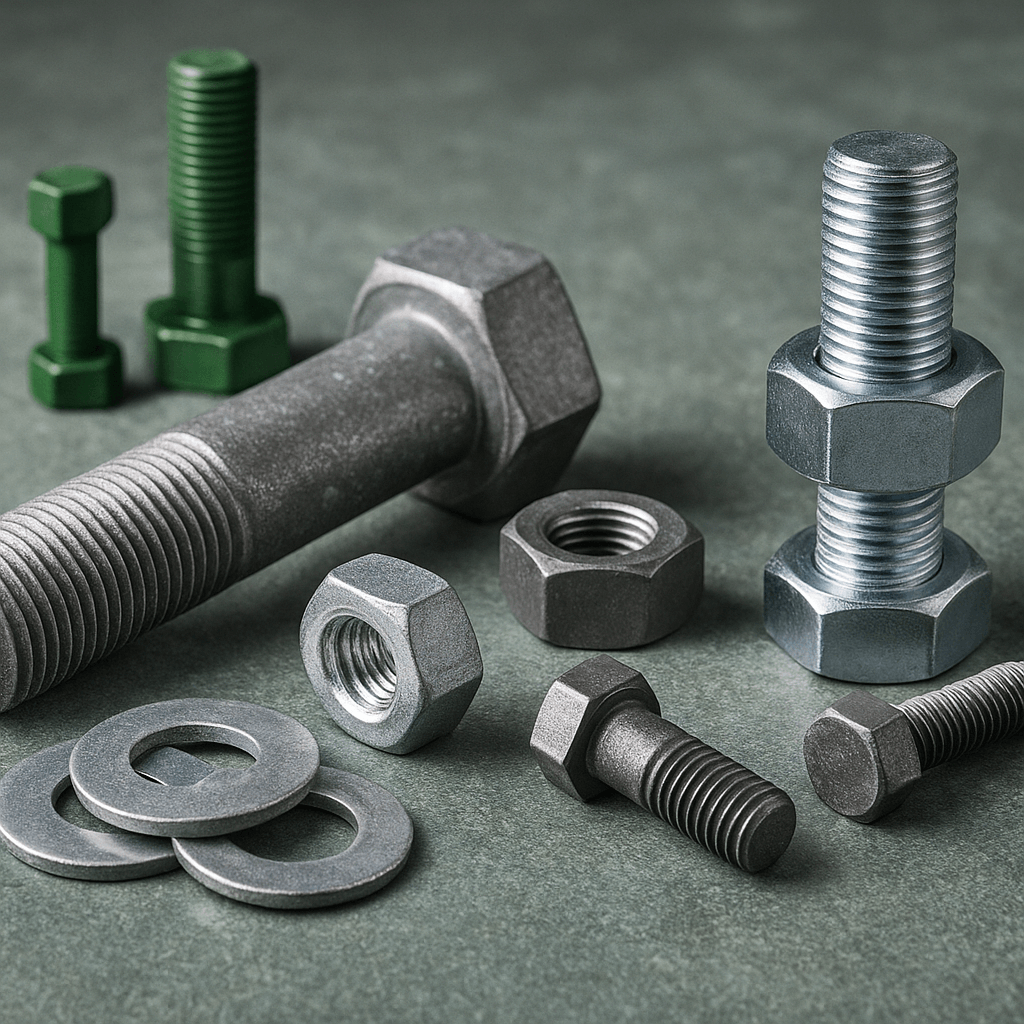

1. Hot-Dip Galvanizing (HDG)

Use Case: Infrastructure, structural steel, and utility towers

Benefits: Thick zinc layer provides superior corrosion resistance, especially for outdoor and submerged environments.

Stats: HDG coatings can last up to 70 years in moderate environments and 30–50 years in coastal zones.

2. Zinc Nickel Coating

Use Case: Automotive, power plants, and equipment exposed to heat

Benefits: Excellent resistance to heat and corrosion; significantly reduces hydrogen embrittlement.

Stats: Offers up to 1000 hours of salt spray resistance, per ASTM B117.

3. PTFE (Polytetrafluoroethylene, or Blue Coating)

Use Case: Offshore drilling, marine platforms, and chemical plants

Benefits: Low friction, high chemical resistance, and exceptional wear durability.

Stats: Reduces required torque by up to 20%, allowing safer tightening without compromising clamping force.

4. Xylan Coating

Use Case: High-pressure pipeline systems and subsea assemblies

Benefits: Combines the properties of lubricants and tough polymers to protect against corrosion and friction.

Stats: Enables torque-tension consistency and maintains effectiveness in temperatures ranging from -250°C to 285°C.

5. Black Oxide

Use Case: Aesthetic finishes and light corrosion resistance

Benefits: Provides mild corrosion resistance and improved appearance while retaining tight tolerances.

Stats: Typically used in indoor or less aggressive environments.

Engineering Advantages of Advanced Coatings

For engineers and procurement leaders, choosing coated fasteners from a high-tensile fasteners supplier Saudi Arabia like Rawabi Fasteners brings multiple advantages:

Lower Lifecycle Costs: By extending service life, coatings reduce the frequency and cost of maintenance.

Improved Torque Control: PTFE and Xylan coatings offer consistent torque, reducing the risk of over-tightening or under-tightening in critical connections.

Environmental Resistance: Ideal for operations in high-humidity, offshore, or chemically aggressive environments common in GCC infrastructure.

Compliance & Safety: Our coatings meet rigorous industry specifications including ASTM, ISO, and Aramco standards, supporting industrial safety and long-term compliance.

Industries That Rely on Coated Fasteners

Rawabi Fasteners has positioned itself as a trusted heavy-duty bolts & nuts supplier KSA, offering custom coating solutions for sectors where failure is not an option:

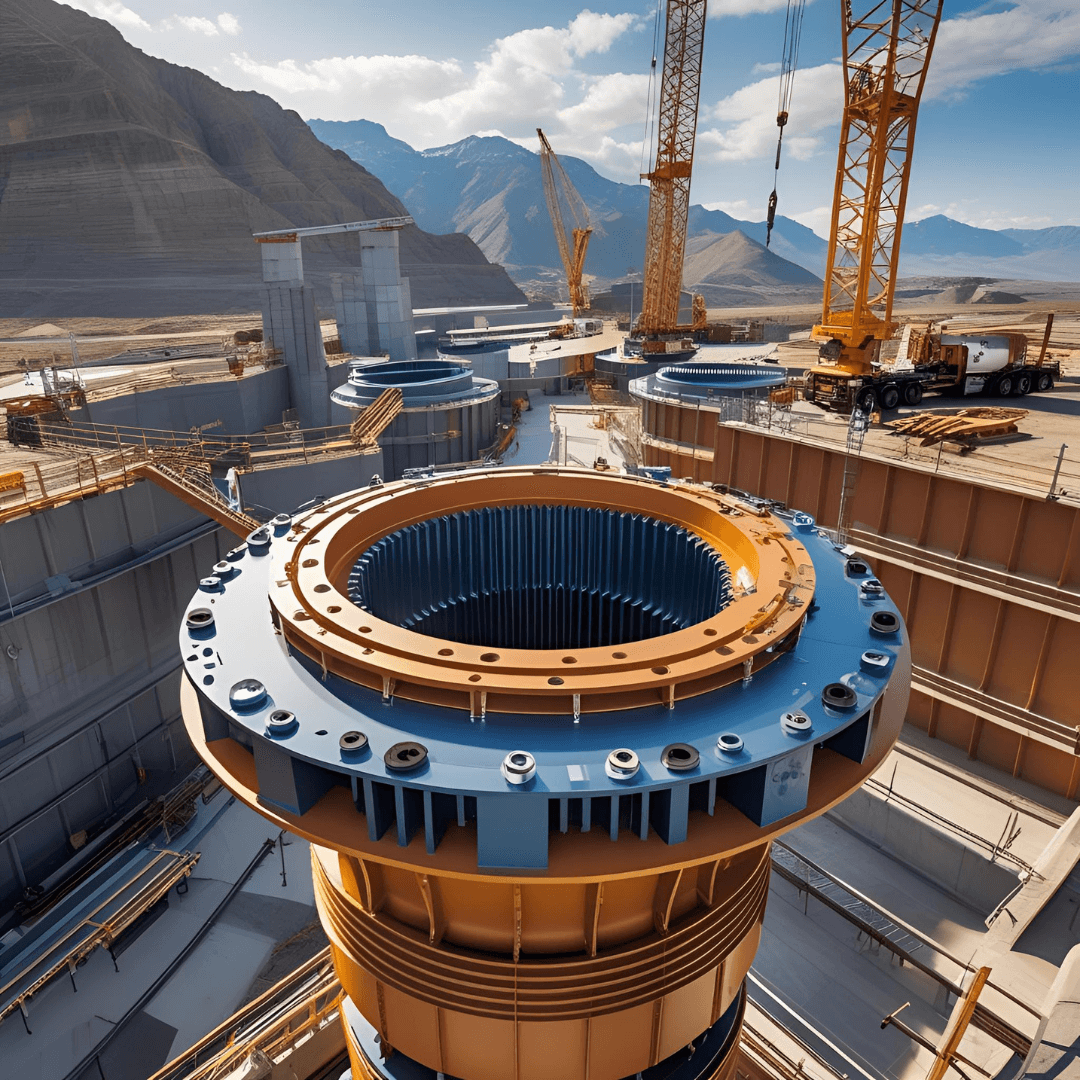

Oil & Gas: Offshore rigs and refineries rely on coated bolts for resistance to saltwater and hydrocarbons.

Marine & Shipbuilding: Fasteners used here must withstand constant salt spray, moisture, and mechanical stress.

Power Generation: Heat and corrosion resistance is vital in turbines and other high-temperature systems.

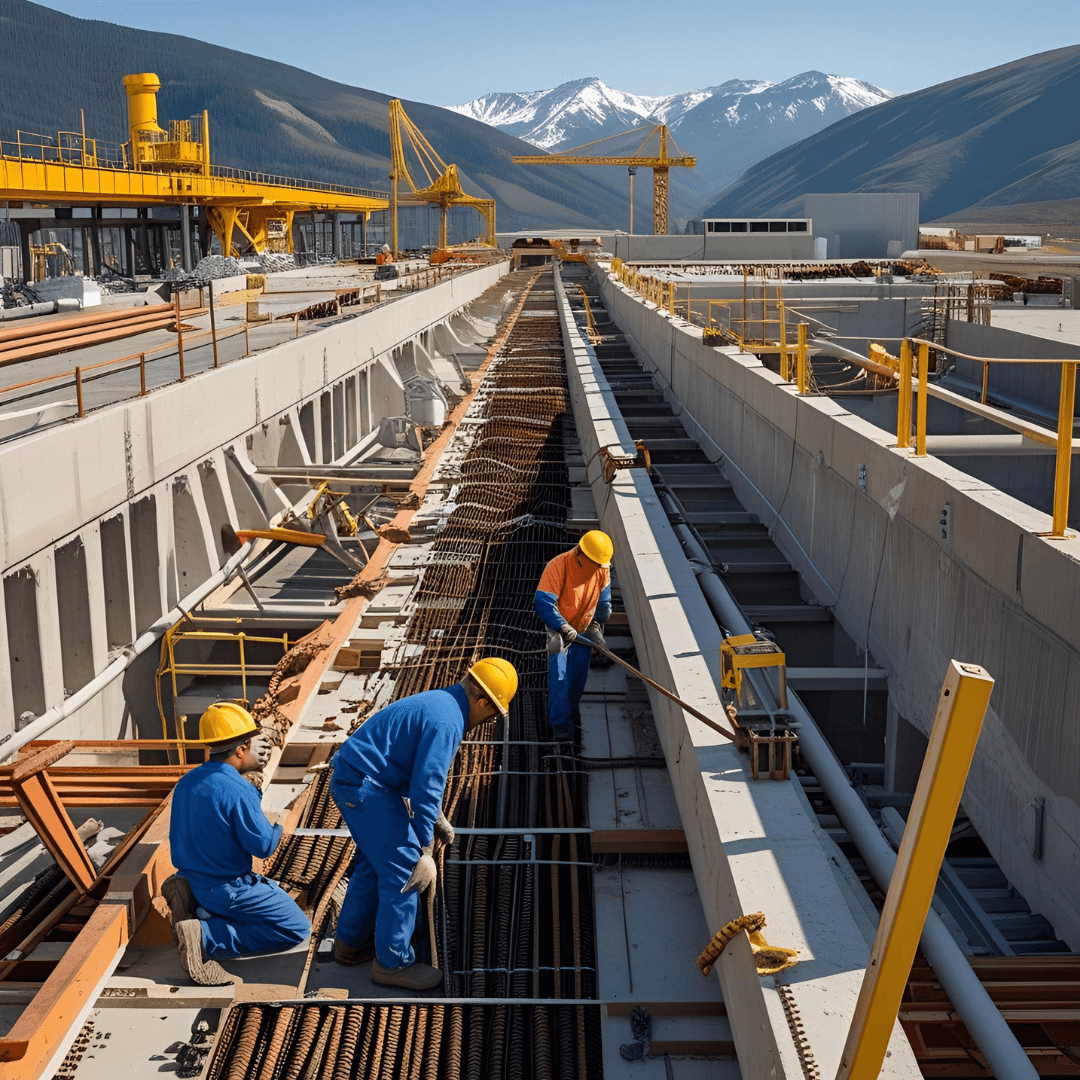

Civil Infrastructure: Bridges, towers, and highways need galvanized fasteners to endure decades of exposure.

Coating Technology in Action: Real-World Impact

In a recent infrastructure project along the Red Sea coastline, Rawabi Fasteners supplied PTFE-coated bolts to a major desalination plant operator. These fasteners demonstrated zero corrosion after 12 months, outperforming standard zinc-coated fasteners that began corroding in less than 4 months. Similarly, our Xylan-coated bolts used in Aramco’s high-pressure pipeline systems showed a 30% improvement in operational lifespan, reducing the frequency of replacement shutdowns.

Why Rawabi Fasteners?

Our commitment to engineering excellence and industry compliance sets Rawabi Fasteners apart. As a key player in localized manufacturing under Saudi Arabia’s Vision 2030, we support national goals while offering unmatched product quality. Our coatings are applied using ISO-certified processes, and every batch is tested for adhesion, salt spray resistance, and mechanical consistency.

We don’t just sell fasteners—we deliver performance-enhancing fastening solutions designed for the unique demands of the GCC. Whether you’re sourcing for mega infrastructure or specialized energy projects, our coatings ensure long-term durability and return on investment.

Final Thoughts

In a region where environmental extremes challenge the very fabric of infrastructure, fastener coatings aren’t optional—they’re essential. Investing in high-quality, application-specific coated fasteners is an investment in reliability, safety, and long-term performance. With a proven track record, engineering expertise, and Aramco certification, Rawabi Fasteners remains the go-to choice for fastener coatings Saudi Arabia, trusted across sectors for solutions that last.

🔩 Looking for corrosion-resistant fasteners that meet your project’s exact specs?

📞 Contact Rawabi Fasteners today and discover how we’re shielding infrastructure—one bolt at a time.