Introduction: Engineering Reliability Where It Matters Most

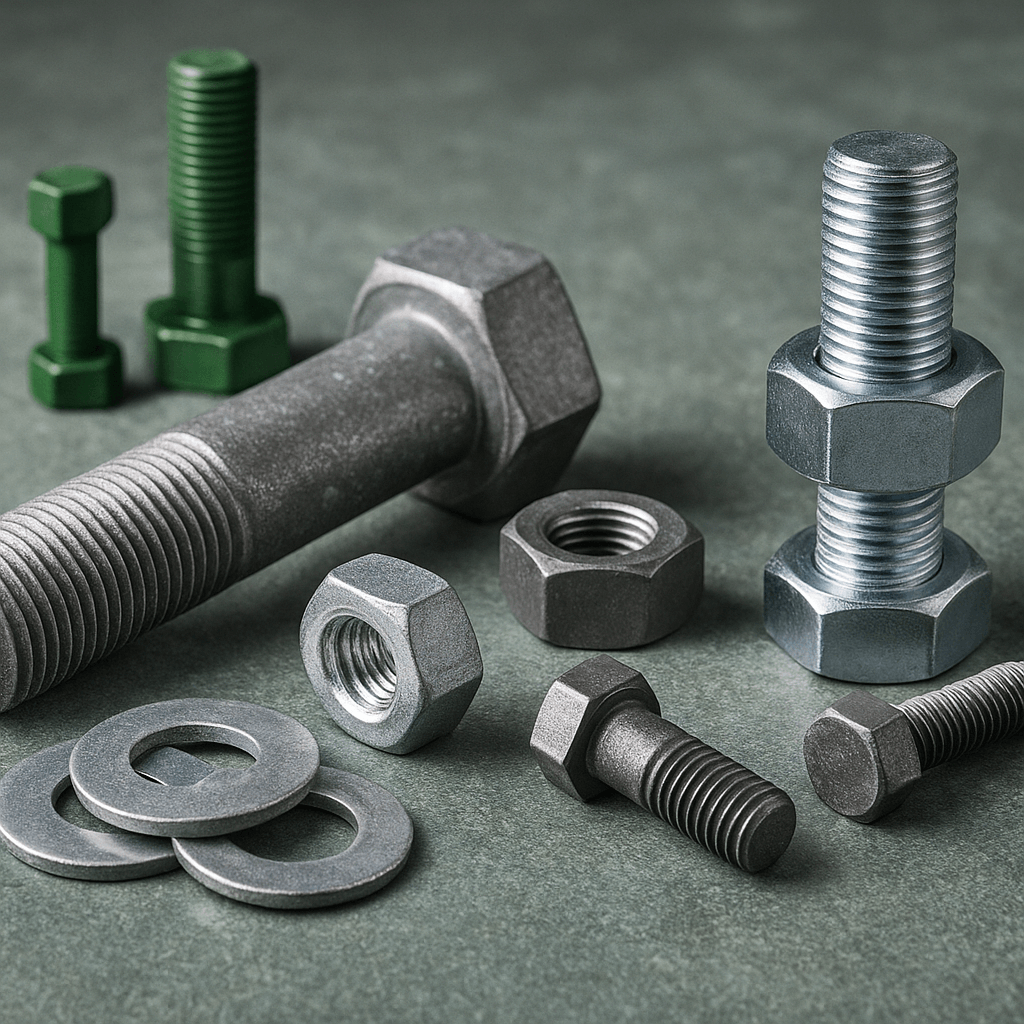

In the harshest industrial settings—whether deep offshore, amid corrosive petrochemical fumes, or under the intense heat of power plants—fasteners are often the silent sentinels of structural integrity.

They hold the components together, sustain operational loads, and ensure safety where failure is not an option. At Rawabi Fasteners, we recognize that true performance starts at the molecular level—with the metallurgical science behind every bolt and nut.

With Saudi Arabia’s continued industrial expansion under Vision 2030, the demand for high-tensile fasteners Saudi Arabia, engineered for resilience and compliance, is surging. As an Aramco-certified fasteners supplier, Rawabi Fasteners is committed to developing specialized alloy solutions built for the rigors of the GCC’s diverse and often punishing environments.

Understanding the Role of Alloys in Extreme Conditions

Fasteners must endure conditions that vary not only in temperature but also in chemical exposure, pressure, vibration, and dynamic load cycles. A standard carbon steel bolt may suffice in low-stress environments, but when faced with saltwater corrosion, cryogenic contraction, or hydrocarbon gas surges, specialized alloys become essential.

Here are the key engineering conditions Rawabi Fasteners considers when selecting materials:

Corrosive environments (marine, chemical plants)

High temperatures (refineries, turbines, furnace rooms)

Cryogenic environments (LNG terminals, cold storage)

High vibration (transport systems, rotating machinery)

Pressure cycling (oil & gas pipelines, power stations)

Rawabi’s Core Alloys and Their Engineering Roles

1. Inconel Alloys (Inconel 600/625/718)

Known for their outstanding high-temperature strength and corrosion resistance, Inconel alloys are commonly used in refineries, power generation, and exhaust systems. Inconel fasteners maintain mechanical properties above 700°C, making them ideal for:

Gas turbines and nuclear reactors

Heat exchangers and high-pressure vessels

Resistance to oxidation and carburization

✅ ASTM B166, B446 compliance

✅ Ideal for: Power plants, flares, gas turbines

2. Monel Alloys (Monel 400/500)

Monel offers exceptional performance in marine and chemical processing environments due to its nickel-copper composition, which resists both saltwater corrosion and acidic attack.

Excellent resistance to hydrofluoric and sulfuric acids

Non-magnetic and spark-resistant

Withstands galvanic corrosion in mixed-metal assemblies

✅ ASTM F467/F468 standard

✅ Ideal for: Offshore oil rigs, shipbuilding, desalination plants

3. Duplex and Super Duplex Stainless Steel

These alloys combine the toughness of austenitic stainless steel with the strength and resistance of ferritic steel, offering the best of both worlds for fasteners exposed to chloride-rich environments.

Up to 2x tensile strength of 316 stainless steel

Outstanding stress corrosion cracking resistance

Excellent in high salinity and acidic conditions

✅ EN 1.4462, ASTM A182 Grade F51/F53 compliant

✅ Ideal for: Petrochemical plants, wastewater, pipelines

4. Austenitic Stainless Steel (304/316/321)

For general-purpose applications, Rawabi offers premium-grade stainless fasteners with added molybdenum for improved chloride resistance.

Non-magnetic, corrosion-resistant

Easy to weld and form

Cost-effective in mid-range applications

✅ ASTM A193 B8/B8M, A320 L7 standards

✅ Ideal for: HVAC, water treatment, storage tanks

Testing and Certification: Quality Without Compromise

Every fastener Rawabi manufactures or supplies undergoes rigorous material integrity verification, including:

Positive Material Identification (PMI)

Hardness & tensile testing

Hydrostatic & fatigue testing

Salt spray & chemical immersion tests

Thermal cycling tests for cryogenic resilience

We comply with the following international and regional standards:

ISO 898-1, ASTM A193/A194, DIN EN ISO 3506

Aramco Engineering Standards (SAES)

ASME Boiler and Pressure Vessel Code

Statistics 2025: The Growing Demand for Specialized Fasteners

As per recent industrial forecasts (GCC Fastener Market Outlook 2025):

The demand for corrosion-resistant fasteners is expected to grow at 12.4% CAGR in the GCC marine and petrochemical sectors.

Over 68% of new power and energy projects in Saudi Arabia now specify non-standard alloy fasteners.

Projects like NEOM, Jafurah Gas Field, and Qiddiya are increasingly relying on custom fastener metallurgy to meet environmental and safety demands.

Conclusion: Why Rawabi Fasteners is the Trusted Alloy Partner

Rawabi Fasteners isn’t just a supplier; we are materials experts and engineering collaborators. Our in-house metallurgists, partnerships with global foundries, and Aramco-compliant production protocols enable us to design fasteners for the most unforgiving environments in the GCC.

Whether your needs involve cryogenic LNG plants, salt-laden offshore rigs, or vibration-heavy turbines, Rawabi’s high-tensile fasteners in Saudi Arabia are the trusted choice—backed by science, tested for performance, and certified for compliance.

Ready to engineer resilience into your next project?

Get in touch with Rawabi Fasteners for custom alloy recommendations and compliance guidance tailored to your site conditions.