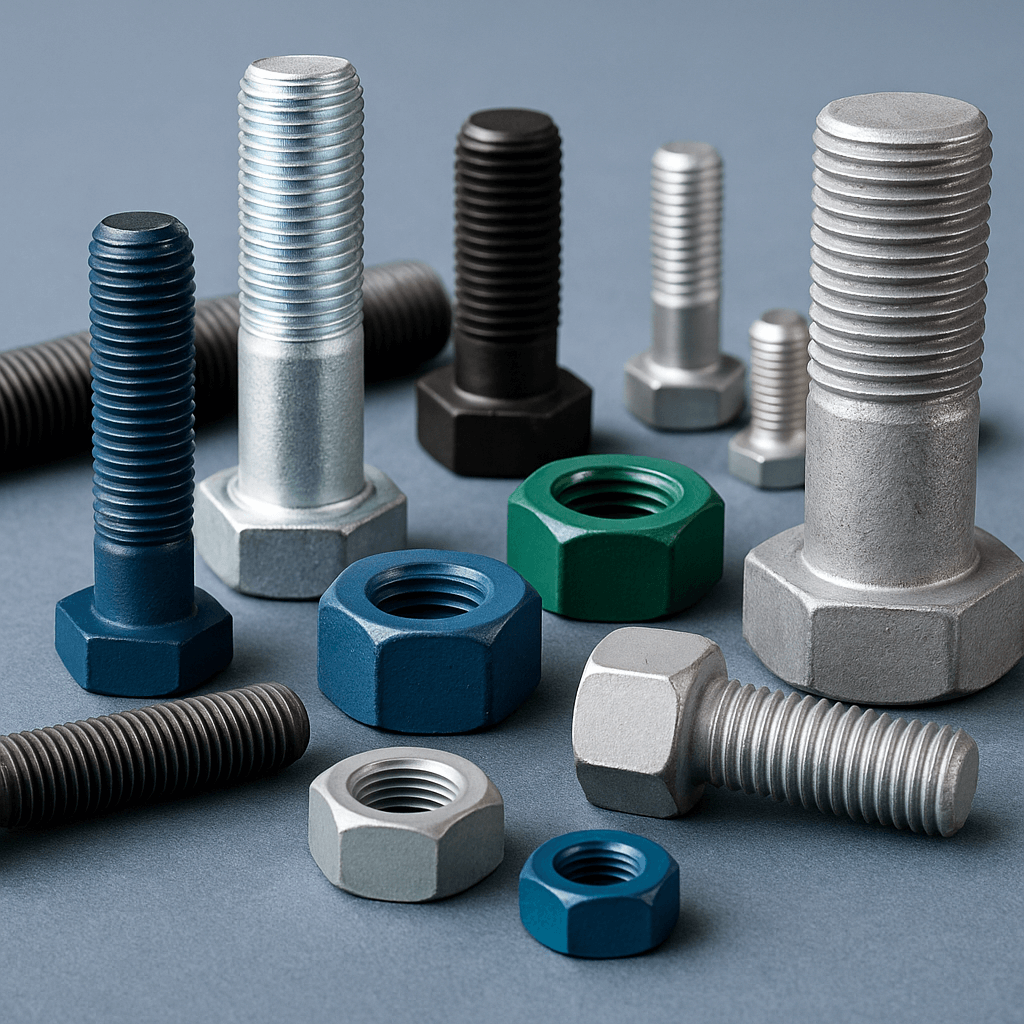

Rawabi Fasteners are built to survive in the harshest GCC Environments. In the unforgiving landscapes of the GCC—where relentless desert heat meets corrosive marine air—industrial durability isn’t just a preference; it’s a necessity.

Infrastructure in Saudi Arabia, the UAE, and the broader Gulf region is consistently exposed to environmental extremes: high salinity near coastlines, scorching temperatures in arid zones, and mechanical stresses from heavy industrial operations.

In these challenging conditions, the smallest components often carry the heaviest responsibility. Fasteners, though compact, play a critical role in structural integrity, safety, and long-term operational efficiency.

Rawabi Fasteners has emerged as a trusted name, engineering fastening solutions specifically designed to thrive in these extremes.

The Environmental Challenges of the GCC

Infrastructure projects in the GCC contend with some of the harshest natural environments on the planet:

-

Temperatures exceeding 50°C in summer months

-

High UV exposure, degrading conventional materials

-

Salt-laden humidity in coastal zones, accelerating corrosion

-

Wind-driven sand and dust, wearing down exposed hardware

-

Dynamic loads from machinery, pipelines, and structural movement

According to a 2024 study by the GCC Infrastructure Research Council, corrosion alone is responsible for 35% of unplanned maintenance costs in industrial facilities across the region.

The selection of appropriate fasteners, therefore, is not just a technical decision but a financial one.

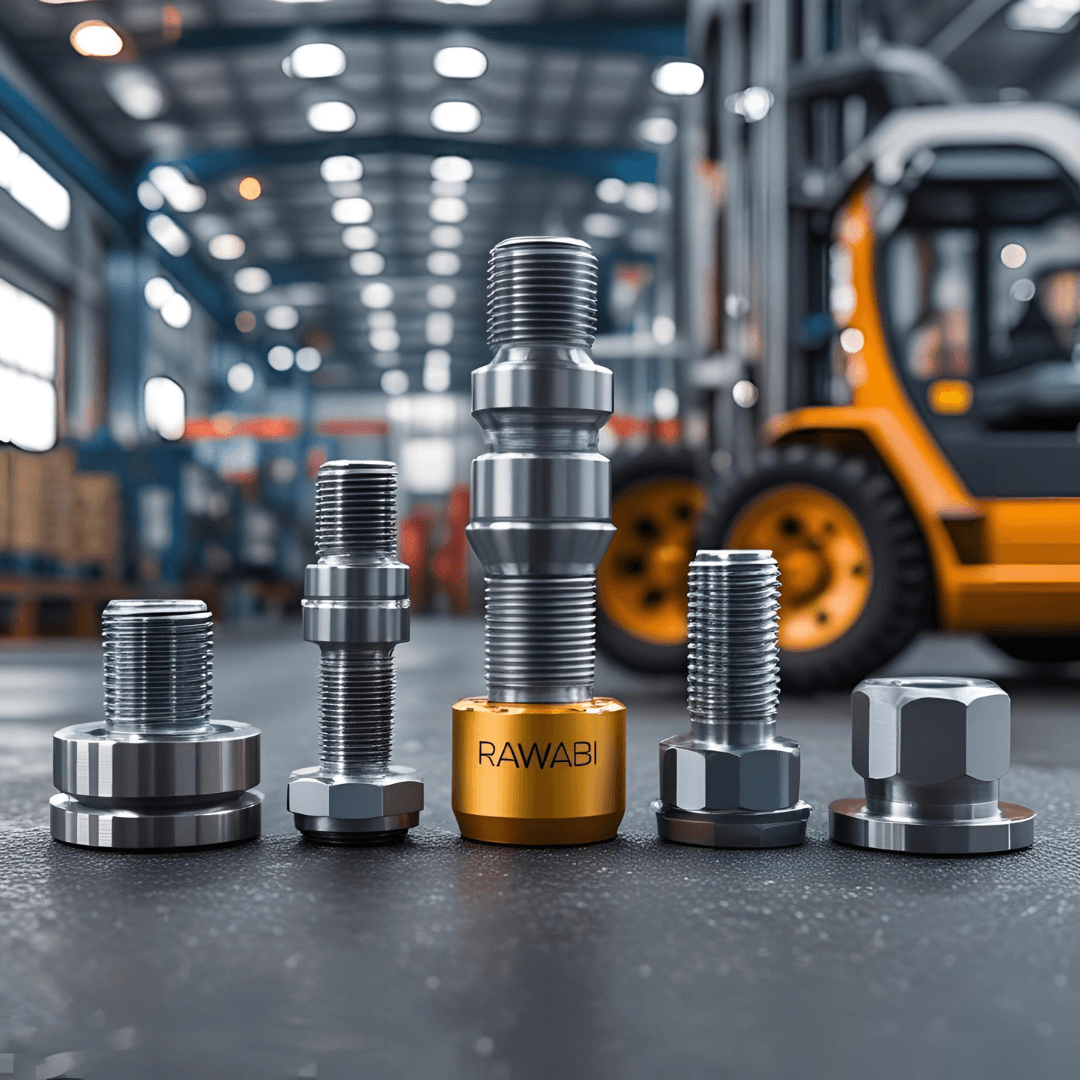

Rawabi Fasteners: Engineered for Harshness

At Rawabi Fasteners, resilience is built into every bolt, nut, and washer. As an Aramco-certified fastener supplier in KSA, Rawabi is trusted to deliver high-performance fasteners that meet the stringent requirements of oil & gas, marine, and infrastructure sectors.

Here’s how Rawabi addresses extreme conditions:

1. Desert-Grade Fasteners

In desert applications—like solar farms, pipelines, and telecom towers—fasteners must endure:

-

Thermal expansion and contraction

-

Sand erosion

-

Foundation instability due to shifting soil

Rawabi’s high-tensile fasteners, manufactured from carbon alloy steels with proprietary heat treatments, are engineered to maintain structural integrity across extreme thermal cycles.

They also undergo simulated field testing, including sand blast testing and thermal fatigue cycles, to validate endurance in desert environments.

2. Marine-Grade Fasteners

Coastal and offshore projects pose another challenge—saltwater corrosion.

For these applications, Rawabi offers:

-

Duplex stainless steel fasteners with superior chloride resistance

-

Zinc-rich epoxy and fluoropolymer coatings

-

Hot-dip galvanized bolts with up to 85μm coating thickness

These coatings reduce corrosion rates by over 70% compared to untreated fasteners, as demonstrated in third-party salt spray test data (ASTM B117).

3. Anti-Vibration and Dynamic Load Resistance

Industrial fasteners face constant vibration in refineries, ports, and heavy equipment.

Rawabi’s precision-machined locking fasteners and thread-locking systems are field-proven to resist loosening under dynamic conditions.

Double-washer locking systems, polymer insert nuts, and anti-rotation pins are just some of the features tailored for high-vibration zones.

Special Teflon-coated bolts provided both thermal stability and corrosion resistance.

Industry Certifications and Compliance

Rawabi’s commitment to performance is backed by global standards:

-

ASTM, DIN, ISO, and BS certifications

-

Aramco vendor approval, ensuring suitability for petrochemical use

-

In-house QA/QC laboratories for tensile, torque, corrosion, and fatigue testing

Each production batch is traceable, with 3.1 Material Certificates and optional 3D CAD models available for design and pre-installation analysis.

Looking Ahead: Fasteners for Vision 2030

As Saudi Arabia expands its infrastructure under Vision 2030, the demand for ultra-durable, low-maintenance components will skyrocket.

From NEOM’s coastal smart cities to Red Sea giga-projects, only components like Rawabi’s engineered fasteners can offer the reliability and endurance that futuristic infrastructure demands.

Conclusion

In environments where failure isn’t an option, Rawabi Fasteners delivers certainty.

Whether holding up a steel bridge in a scorching desert or anchoring a marina pier in saltwater, our fasteners are built to perform—no matter how harsh the environment.

By prioritizing material science, coatings technology, and application-specific engineering, Rawabi ensures that the smallest components make the biggest difference.